Chemical Park with a tradition of 120 years

Did you know that Bitterfeld-Wolfen is one of the oldest location of the chemical industry in Germany?

Companies of the chemical industry were established here 120 years ago already - attracted by the cost-favourable lignite deposits and raw materials. Bitterfeld-Wolfen has gained particular importance by the production of basic chemicals.

Based on chlorine, other products like pesticides or colourants have been developed, and new production lines have been erected.

120 years of chemistry

Tradition and innovation in Bitterfeld-Wolfen

The history of the chemical location Bitterfeld-Wolfen is characterized by the ingenuity of the people. Since 1893 , specialists have investigated and developed new products and more efficient procedures. Explore a location with tradition and interesting prospects.

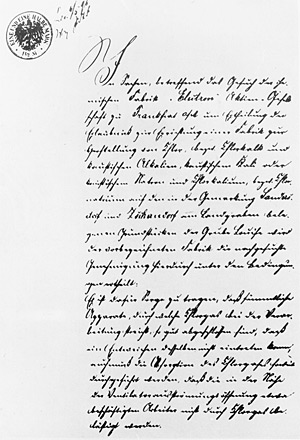

Griesheim commissioned the first electrolysis plant for alkali-metal chlorides on 16 October 1894. It was the first large technical plant of this type with 90 Griesheim cells in Bitterfeld-South.

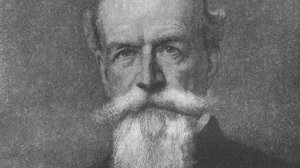

In November, the electrolysis plant for alkali-metal chlorides of Elektrochemische Werke started production. The production plant was built in Bitterfeld on the initiative of Walther Rathenau. From 1894 - 1907, Rathenau was the managing director of Elektrochemische Werke.

In 1895, a colourant factory was erected in Greppin. The Farbenfabrik (colourant factory) started its production by commissioning a plant for the fabrication of benzidine, an intermediate product for the colourant Ruby.

In 1898, Griesheim and Elektrom merged under the firm "Chemische Fabrik Griesheim Elektron".

In 1925, I.G. Farbenfabrik AG was founded. The factories in Bitterfeld and Greppin belonged to "Betriebsgemeinschaft Mitteldeutschland" (Factory Association Central Germany), having its registered office in Bitterfeld.

On the basis of the post-chlorinated PVC developed in Bitterfeld, the first synthetic artificial fibre of the world (Pe-Ce fibre) was produced in Filmfabrik Wolfen in 1934.

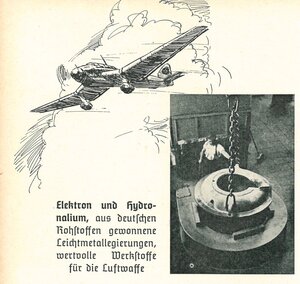

In 1936, the world's first colour film was produced in Wolfen, and the first manufacturing facility for PVC started its production in Bitterfeld. Filmfabrik Wolfen became the largest manufacturer of chemical pulp in Europe.

In 1938, the first synthetic-resin ion exchanger (WOFATIT) was produced in Wolfen. Paul Robert Grießbach realized that permanently new applications can be derived from the different variants of the parent materials for synthetic-resin ion exchangers.

In the same year, the new material Igurit, later Carbon, was developed on the basis of impregnated electrographite.

1939 During World War II, the production of I.G. Farben factories was shifted to armament industry. In the main, this referred to basic and fabricated materials, e.g. nitric acid, hydrochloric acid, cellulose, artificial silk and light metals. Shortly after the outbreak of the war already, prisoners of war and forced labourers of different nationalities were occupied as additional workers in the factories.

During World War II, the production was shifted to war conditions.

1945 The end of the war also meant the end of I.G. Farbenindustrie AG. In the different occupation zones, the I.G. factories were controlled by the occupation forces, and the range of products was dictated.

In 1946, the factories were incorporated in the Soviet enterprises (SAG - "Sowjetische Aktiengesellschaften") "Kaustik" (factories in Bitterfeld), "Kraska" (colourant factory in Wolfen), and "Photoplenka" (Filmfabrik Wolfen).

In 1952, the SAG were handed over to the state of the GDR, and VEB Elektrochemisches Kombinat Bitterfeld, VEB Farbenfabrik Wolfen and Film- und Chemiefaserwerk AGFA Wolfen were founded.

In 1959, the first Bitterfeld Conference under the slogan "Socialist working, living and learning" was held in the Palace of Culture "Wilhelm Pieck".

In 1969, VEB Elektrochemische Kombinat Bitterfeld and VEB Farbenfabrik Wolfen (parent company) merged under the firm VEB Chemiekombinat Bitterfeld (CKB). In 1989, CKB had a workforce of approx. 30,000 employees, of which approx. 18,000 in Bitterfeld-Wolfen, manufacturing approx. 4,500 products for a total goods value of approx. 5 billion GDR Marks.

In 1970, VEB Fotochemisches Kombinat Wolfen was founded, with headquarters in VEB ORWO Filmfabrik in Wolfen and its subsidiaries. Approx. 15,000 employees of VEB Fotochemisches Kombinat Wolfen manufactured 360 different products in 1,800 formulations.

In 1975, a comprehensive rationalization, stabilization and modernization program was launched to overcome instabilities in CKB.

In 1982, the chlorine IV plant was put into operation.

in 1990, the headquarters were taken over in the stock corporations Chemie AG Bitterfeld-Wolfen and Filmfabrik Wolfen, and incorporated in their economic and legal structure.

Furthermore a governmental committee was established to solve pending ecological and economical problems in the Bitterfeld-Wolfen region.

In 1990, the newly founded Chemie AG could not be privatized in its entirety. Thus the concept of the chemical park was developed to maintain the chemical industry location, with the following strategy:

- Demolition of closed-down plants and buildings as well as removal of ecological hazards

- Sale/privatization of individual business segments (e.g. detergents, cast products, pipe extruders...)

- Spinning off/privatization of required services (energy generation, maintenance and repair, telecommunication...)

- New settling of chemical and near-chemical companies (Sidra, Bayer, Heraeus, Ausimont, Akzo...)

- Establishment of competitive disposal structures (water treatment plant, disposal sites...)

- Settling of industrial undertakings by utilizing the numerous existing buildings and properties.

In 1993/1994, the following companies emerged from Chemie AG.

- Chemie GmbH Bitterfeld-Wolfen

- ChemiePark Bitterfeld GmbH

- Bitterfelder Vermögensverwaltung Chemie GmbH

The Wolfen-Thalheim Industrial Park was founded on the premises of the former Filmfabrik Wolfen in 1994.

In 1997, ChemiePark Bitterfeld Wolfen GmbH was founded, aiming at the joint marketing and development of the two premises.

1998 Privatization of ChemiePark Bitterfeld Wolfen GmbH to the Spezialtechnik Dresden group, which failed however.

In 2001, a successful second privatization of ChemiePark Bitterfeld Wolfen GmbH to the Preiss-Daimler group was achieved.

In total, more than 400 projects covering an investment volume of 230 million Euros were realized in the period between 2001 and 2008 under continuing business operation at the chemical location Bitterfeld-Wolfen. At the same time, another 83 million Euros were invested in the refurbishment of buildings.

The extreme flood situation in 2002 and the flooding of Lake Goitzsche had a significant impact on the investments.

In 2003, the refurbishment of roads, potable-water, industrial water and clean-water systems as well as wastewater lines was undertaken.

In 2004, eight new water retention basins were built and a modern water-management information system was implemented. For the optimal supply of the companies in the Chemical Park, 2.2 kilometres of pipe racks were newly erected and 15.8 kilometres were refurbished.

Listed buildings were also refurbished for use as office and training facilities.

In 2005, service and industrial buildings were modernized.

In 2006, green spaces were laid out and new trees were planted.

By 2012, about 360 companies providing approx. 11,000 jobs had settled on a total area of 1,200 hectares, of which 170 hectares are still available.

In 2013, GELSENWASSER AG acquired 94% of the shares in P-D ChemiePark Bitterfeld Wolfen GmbH.